We develop economical lightweight components by using mathematical optimization

Applicable to any industry and any manufacturing process

Our Services

Revolutionary component development - comprehensively implemented

For which of your components would redevelopment be the most profitable e.g. in terms of lightweight design? Which manufacturing process (incl. 3D printing) is suitable for producing the component and which process offers the best cost-benefit ratio? We clarify the question of economic efficiency and identify which of your company’s components we believe provide you with the most benefits. The identification is free of charge and provides you with a non-binding overview of the hidden potential within your assemblies. You can arrange a free consultation by going to our contact request page. If you already have part in mind, you can also use our free automated identification tool: amvaluation

Through our simulation driven component development process (see development process), we are able to tailor your part designs perfectly to your applications. We can prioritize several different objectives such as lightweight design, minimum manufacturing costs or the increase/reduction of thermal conductivity. Lightweight design is often accompanied by reduced manufacturing costs. In doing so, we can variably influence the relationship between the degree of lightweight design and the costs in order to generate the optimum for your application. The resulting designs provide the maximum performance with the minimum material used at the lowest possible manufacturing cost. At the same time, we guarantee the operational safety and manufacturability of the components we design. Not able to imagine the difference yet? Click here for some sample projects with before-and-after comparisons from the automotive– and machinery industry.

If you have already performed your own topology optimization, we also offer geometry return of the results into CAD solid models separately. In doing so, we guarantee a minimal deviation between the result of the topology optimization and the final component geometry. Uneven, discontinuous, “not watertight” and generally error-prone STL files are no problem and can be exported in STEP or IGES file format after the return process. The files are subsequently fully editable in any common CAD program.

By combining simulation and physical testing, we reliably ensure the manufacturability and fatigue strength of your component. We have a database of a wide range of material models that are used to reliably calculate the fatigue life of these components. The use of process simulation of the various manufacturing methods, 3D printing or conventional, enables the avoidance of potential manufacturing issues down the line.

Through our large network of manufacturing partners, we can find and commission the ideal production partner for your component. We coordinate the manufacturing and ensure that delivery times are met. All of the required manufacturing parameters are defined by us in consultation with you, so there is no need for specific manufacturing know-how on your part. We have carefully selected our manufacturing partners in order to guarantee the highest quality. In addition, we have extensively tested manufactured components from our partners through both non-destructive and destructive testing to eliminate any uncertainties. Materials used during manufacturing are also qualified by our own in-house testing in order to verify potentially inaccurate manufacturer material specifications.

Your Benefits

Tailored components

Cost reduction

By saving material or changing the previously used manufacturing process, production costs are drastically reduced. You don’t have to purchase costly software or machinery, and you don’t have to train employees to use such tools. In addition, we can offer the best prices for manufacturing through our network of manufacturing partners. Getting started is straightforward with our free part identification service.

Lightweight design

Lightweight design plays a very important role, especially for moving components. Reduced weight inherently reduces dynamic forces and provides you with benefits from secondary effects such as: increased travel speed for your production equipment, reduced energy consumption, increased tool life or simplified component handling.

Optimized thermal behavior

The aim of component optimization can also be to improve the part’s thermal properties, so that cooling and heating problems are eliminated by the optimized component structure. Depending on the application, you benefit for example through less wear, increased performance in thermally-stressed components and reducing required additional cooling and heat sources.

Shortest development time

Reduce your time-to-market. By eliminating manual design steps in our development process, we can develop parts up 80% faster while being able to respond flexibly to your desired changes.

Development example - machinery

Lightweight Pick & Place Machine

oder

By optimizing four components of the pick & place machine, the moving mass was reduced by 29.8 kg. The components were optimized for three different manufacturing processes in order to generate an ideal relationship between cost and performance. Eleven components were combined into four parts. This improves the assembly effort and handling. Two linear guides and 25 screws were saved. Fatigue strength and manufacturability are fully assured. Due to the reduced moving mass, 52% less energy is required to perform the movements. The result is either 34% faster production or 52% reduced energy costs. 1270€ of energy costs are saved per year per machine.

We investigate the potential of optimized components for your machines free of charge.

Before / after comparison & technical data of the optimized components

- Move the slider

Bitte führe ein Update deines Browsers durch oder verwende einen der folgenden Browser:

Google Chrome Version 23 oder höher

Firefox Version 65 oder höher

Opera Version 19 oder höher

Microsoft Edge Version 18 oder höher

iOS Safari Version 14.3 oder höher

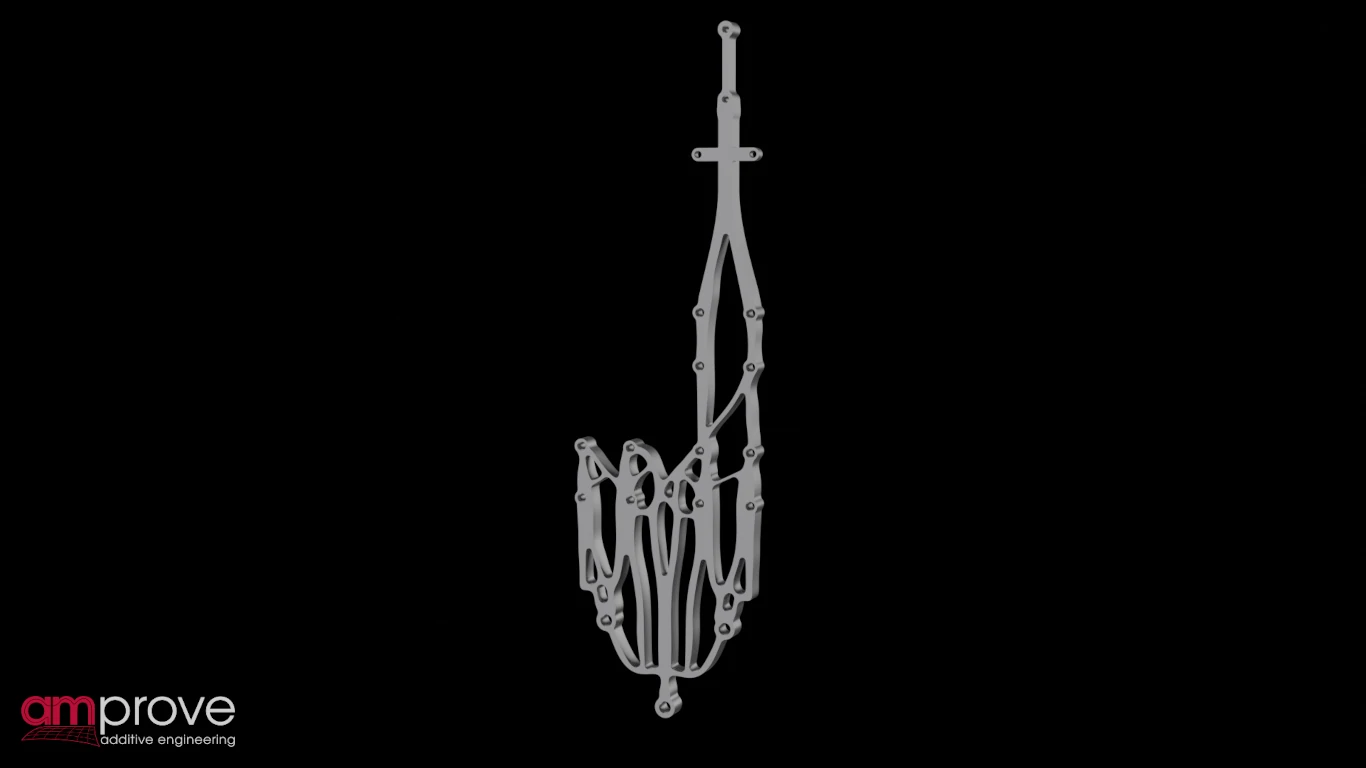

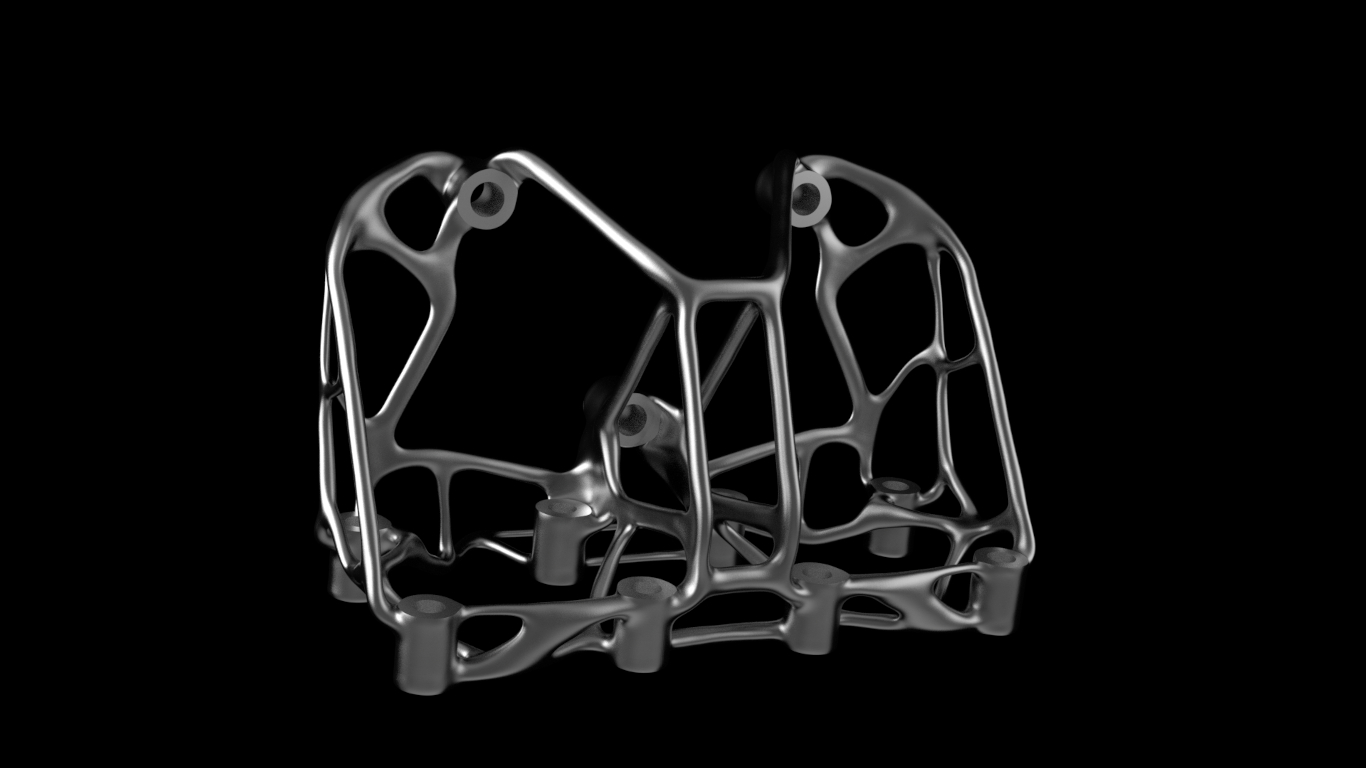

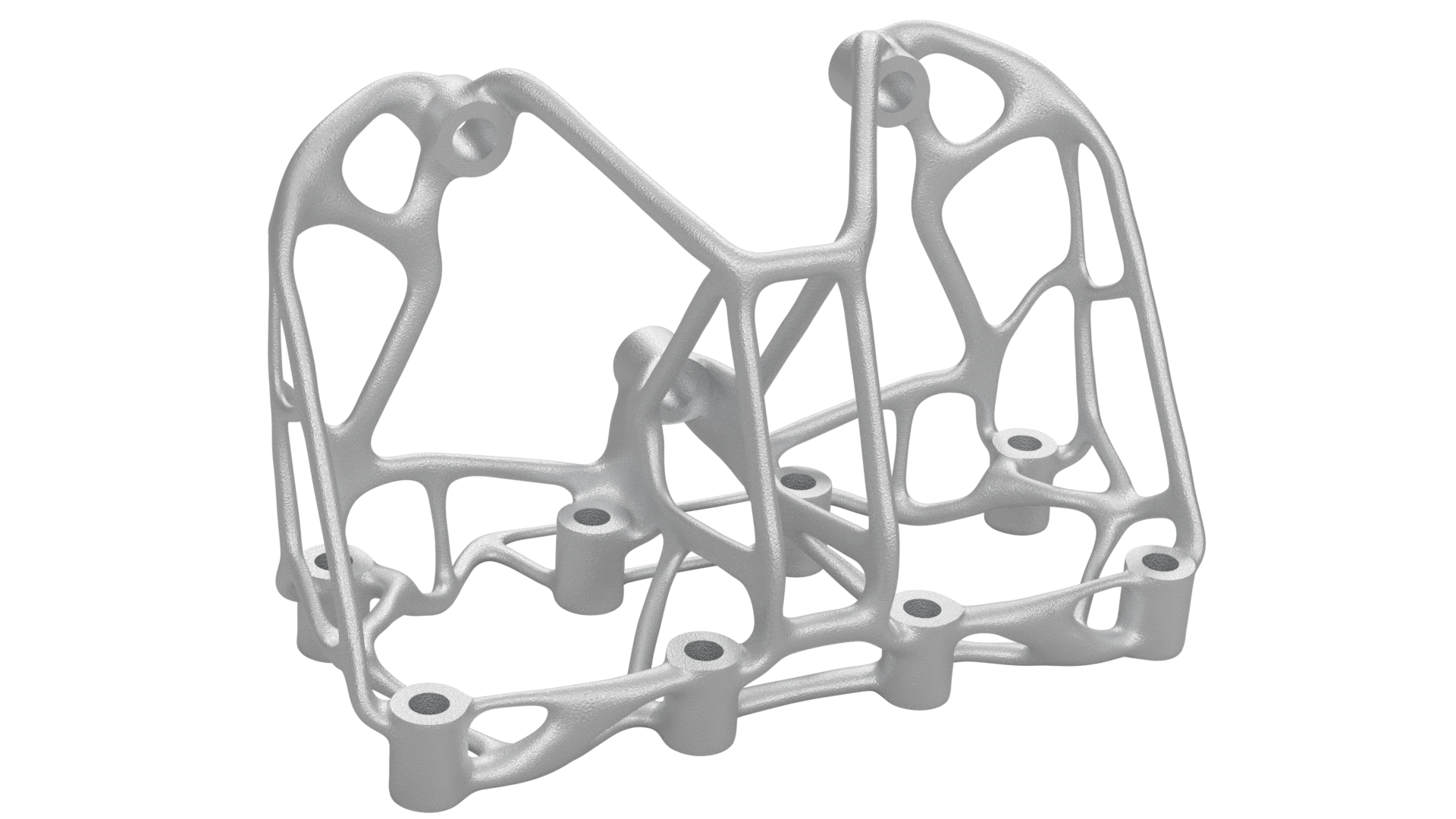

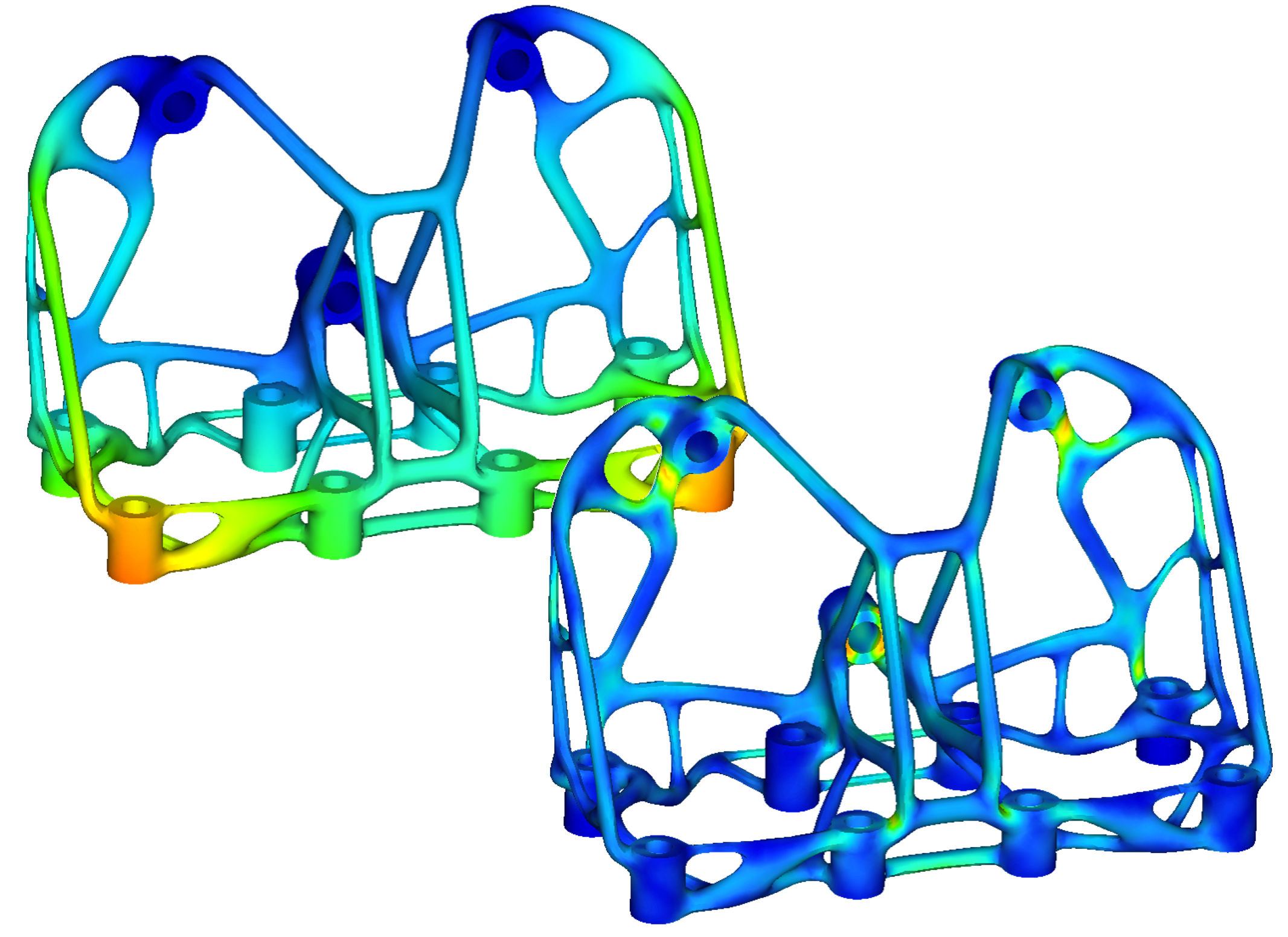

Connection Y - Z axis

Mass before

14,64 kgMasse after

2,28 kgMass reduction

84,45 %Components combined

5 in 1Saved

1 linear guide, 13 screwsManufacturing process

Selective laser meltingMaterial

AlSi10Mg

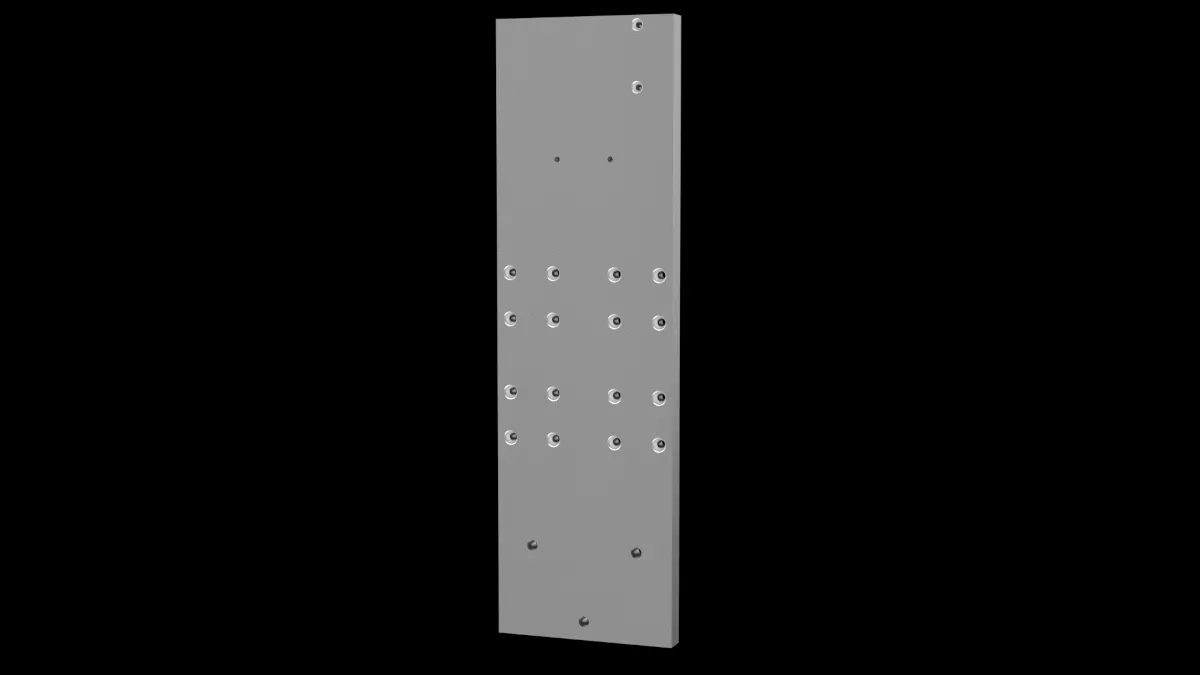

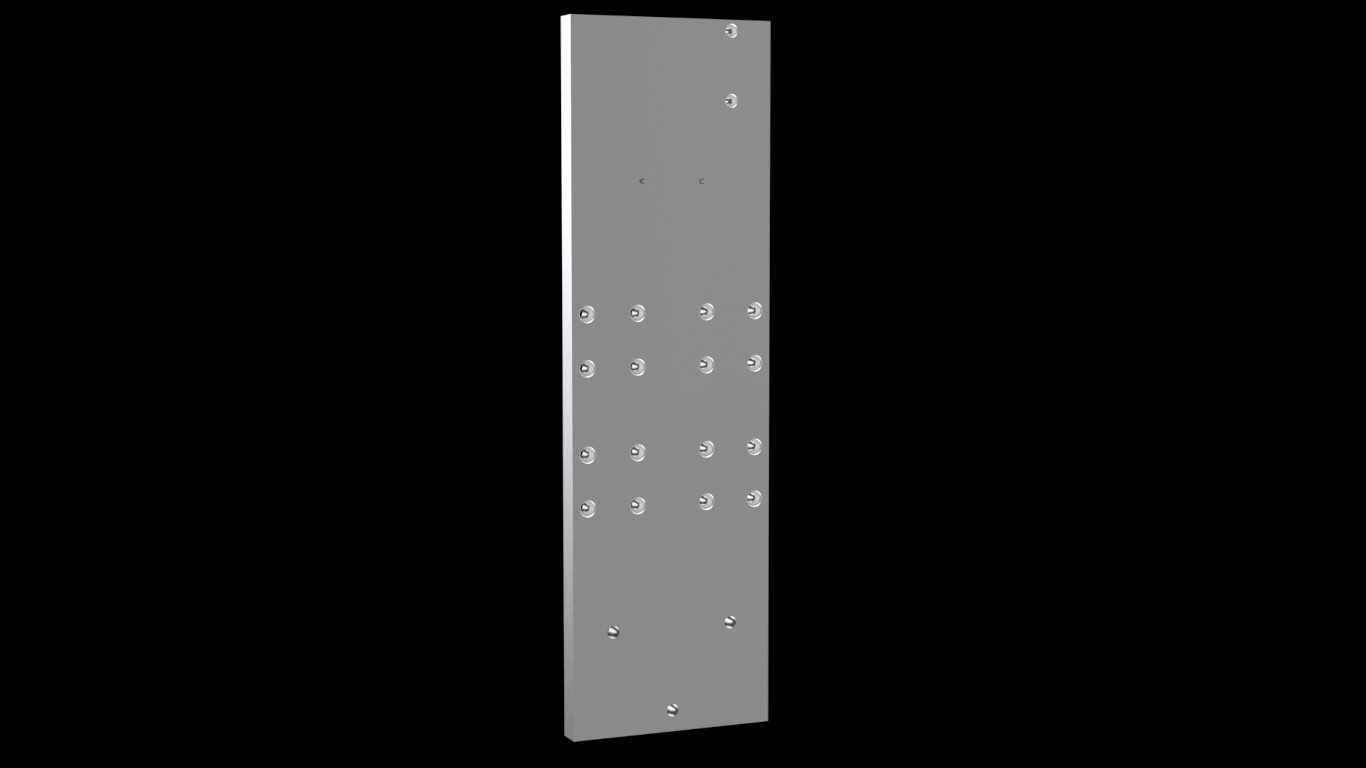

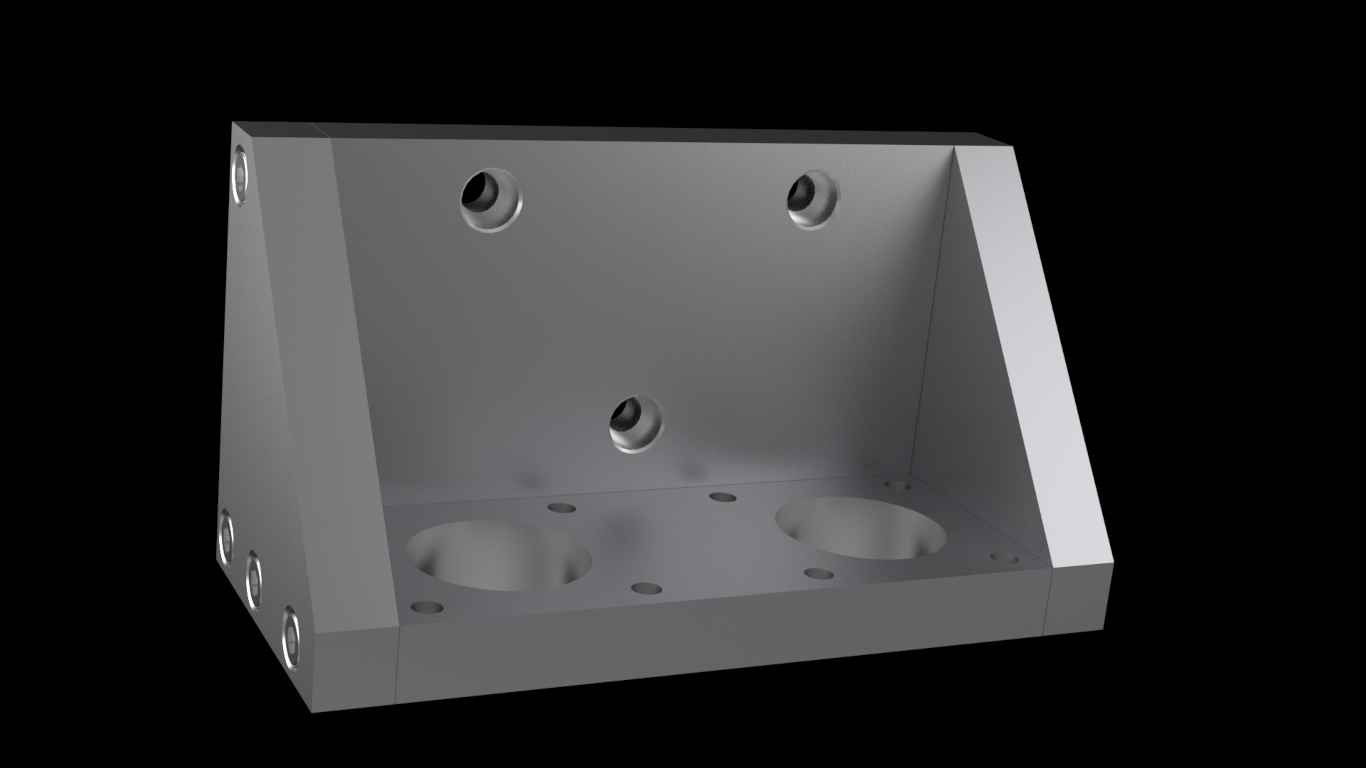

Base plate Z-axis

Mass before

8,91 kgMass after

1,17 kgMass reduction

86,87 %Components combined

2 in 1Saved

1 linear guide, 4 screwsManufacturing process

Water jettingMaterial

EN AW 6060 T6

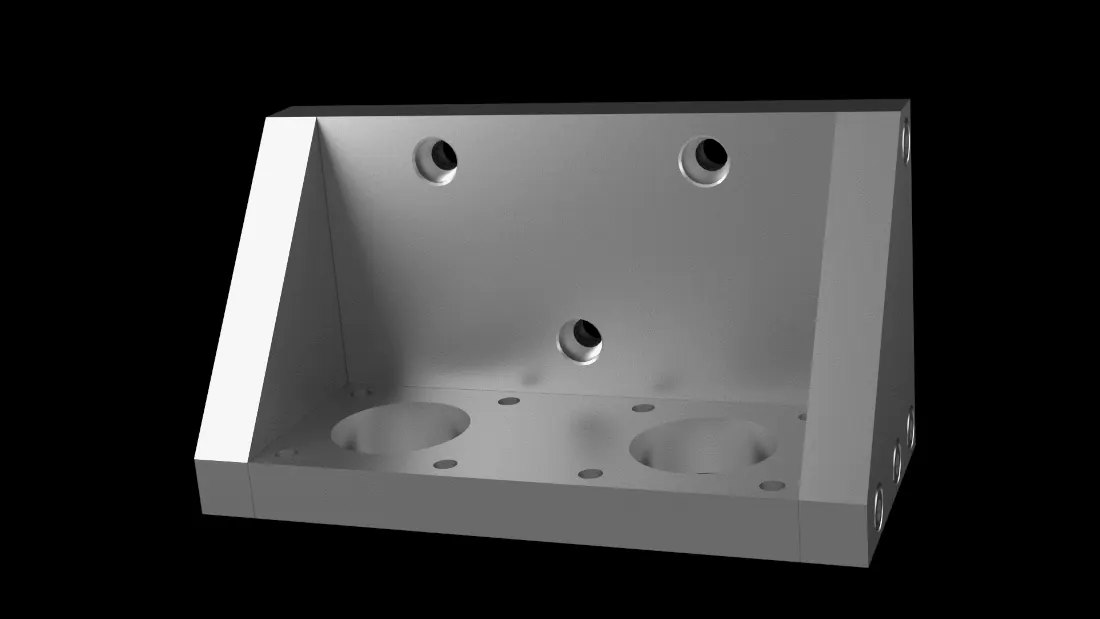

Console pneumatic unit

Mass before

5,12 kgMass after

0,46 kgMass reduction

91,01 %Components combined

4 in 1Saved

8 screwsManufacturing process

Selective laser meltingMaterial

AlSi10Mg

Gripper

Mass before

333,27 gMass after

53,25 gMass reduction

84,02 %Manufacturing process

Selective laser sinteringMaterial

PA12Quanitity installed

4We would be happy to discuss possible applications of optimized components on your machines/plants/.. and look at other potential components.

Development example - Automotive

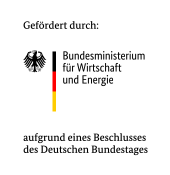

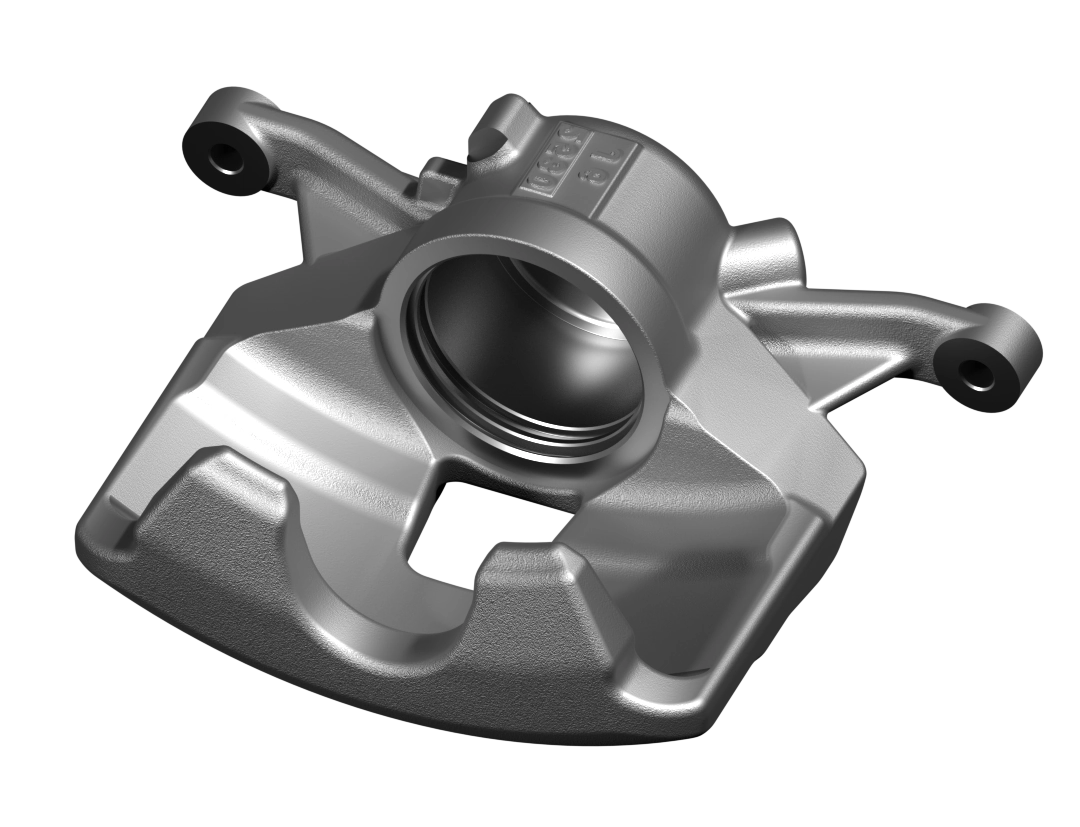

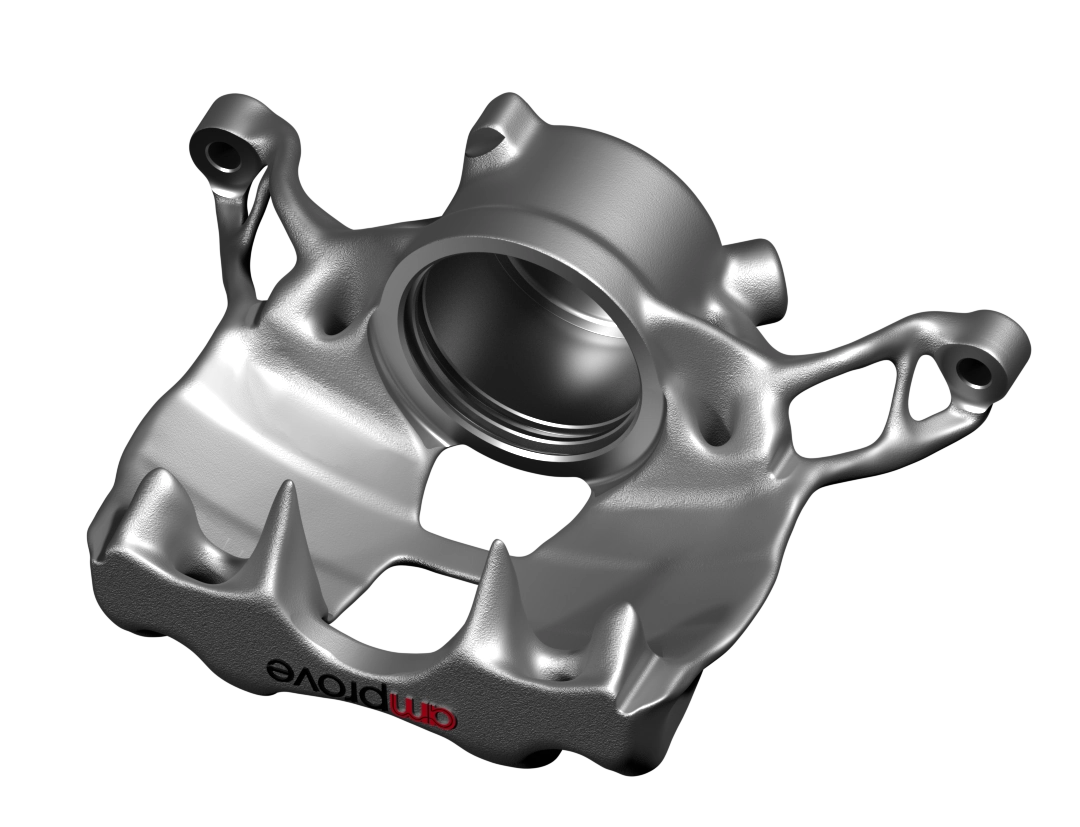

Lightweight caliper for volume models (fist caliper)

Initial component

amprove Design

Initial component

amprove Design

Development result

During the optimization of the brake caliper from the current model of a German car manufacturer, the development focused on reduced production costs through lower material usage. The result of our optimization was a brake caliper with 20% lower mass and per-unit costs reduced by 0.15€. In addition to lower energy consumption, the lighter construction also results in advantages for driving dynamics by reducing the unsprung mass. The optimization of cost-effective lightweight components can be applied to various vehicle parts in quantities ranging from a few thousand up to millions to achieve a large scope.

We would be happy to discuss possible applications for optimized components in your vehicles and to help identify other potential use cases.

&

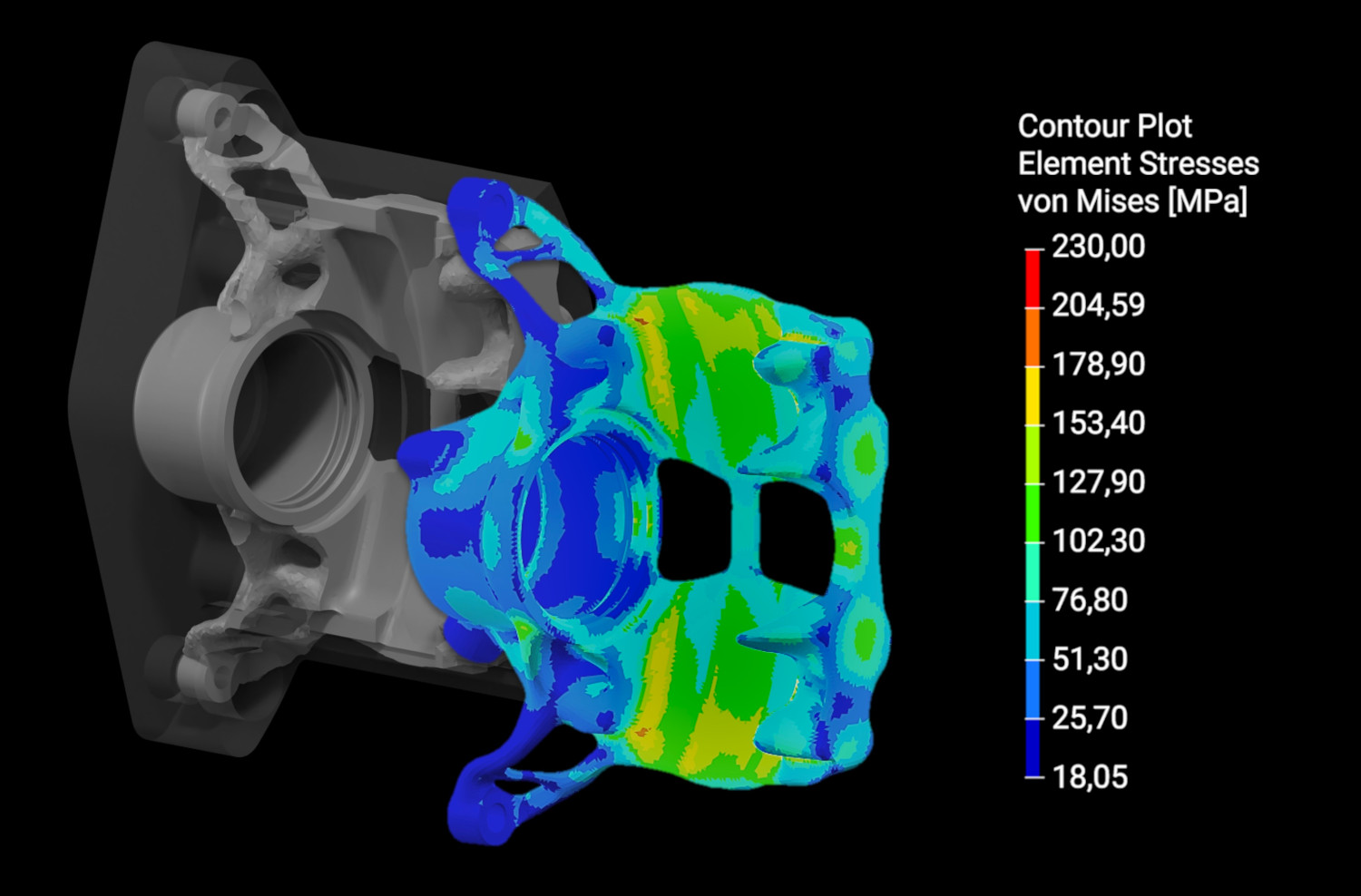

Performance Parameter

Mass reduction

-20 % (663g)Stress reduction

-22 % (-60 MPa)Stiffness increase

+26 % (-0,37ml @ 150 bar)The most important goal besides mass reduction for this application (high-volume production) is to minimize the maximum stress. This makes it possible to use a lower-alloy, less expensive material. By doing so, the per-unit costs can be further reduced. The stress reduction is achieved by a bionic geometry that is suitable for the prescribed load path. At the same time, the new component structure increases the stiffness of the caliper by 26%, which improves how the brake pedal feels.

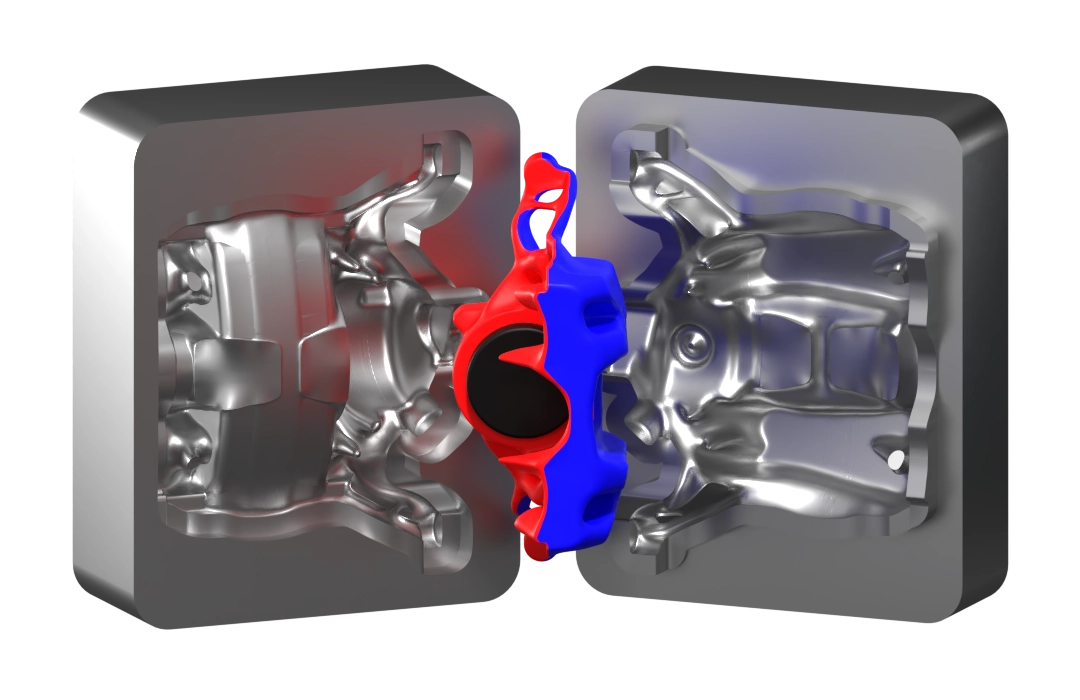

Manufacturing

Unit cost reduction

-$0.17Manufacturing process

Casting with permanent molds/modelsMaterial

Galvanized cast ironTool durability

Identical to initial componentTool

2 part designThe biggest challenge in the development of lightweight cast components is to ensure economic manufacturability. Mass reduction lowers material costs and thus the price of the blank. At the same time, the mold manufacturing costs must be kept low in order to enable overall cost reduction. For this brake caliper, a two-part mold design with a free-form parting line was generated. The figure illustrates the parting line between the blue and red marked areas. With our development process, we have the possibility to ensure demoldability even for the most complex components and to enable uniform solidification. During development, we also simultaneously influence the tool manufacturing costs via the component geometry, to enable a reliable and economic production.

We would be happy to discuss possible applications for your vehicles and to identify other potential components

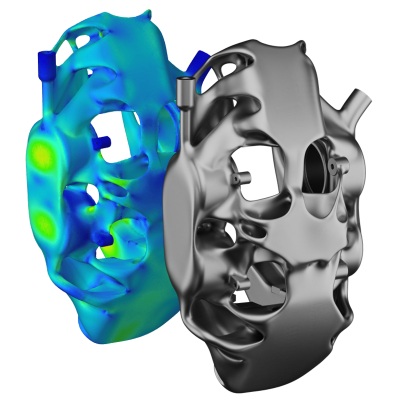

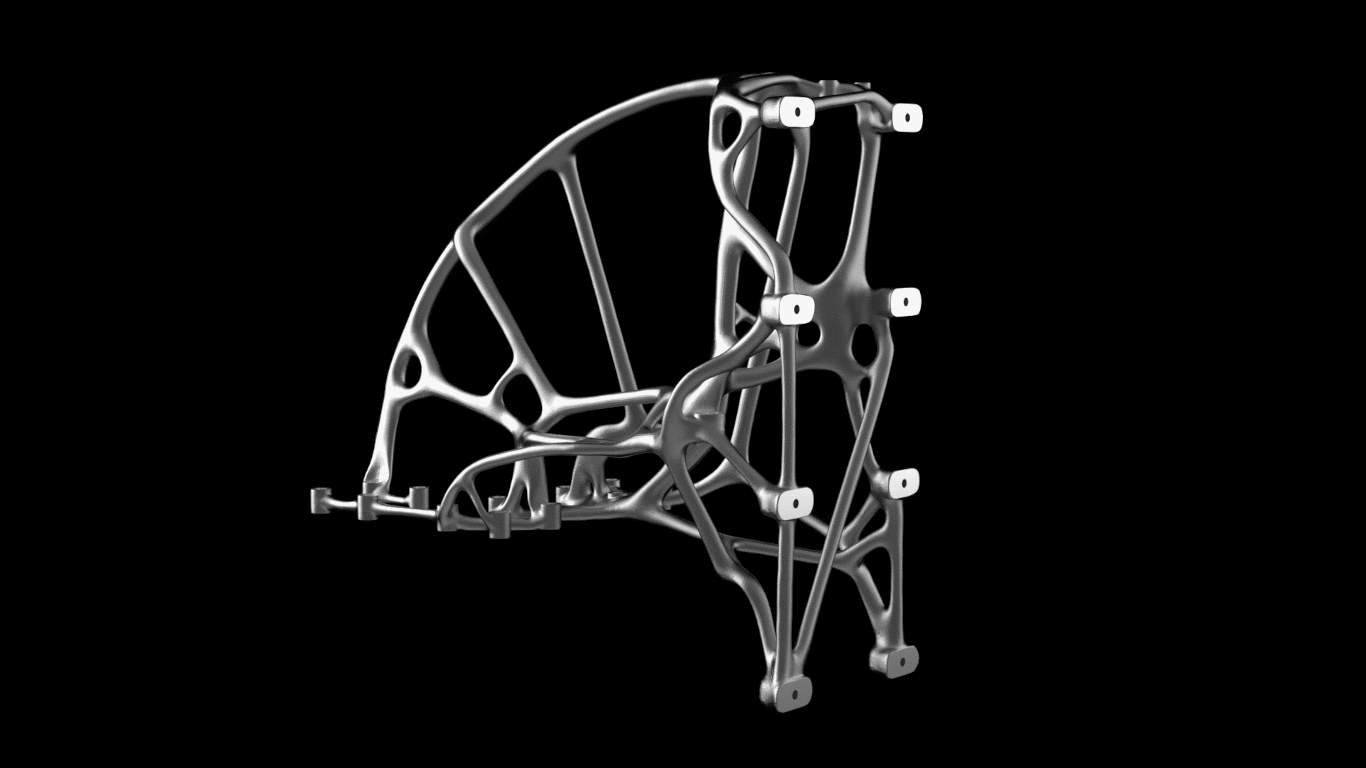

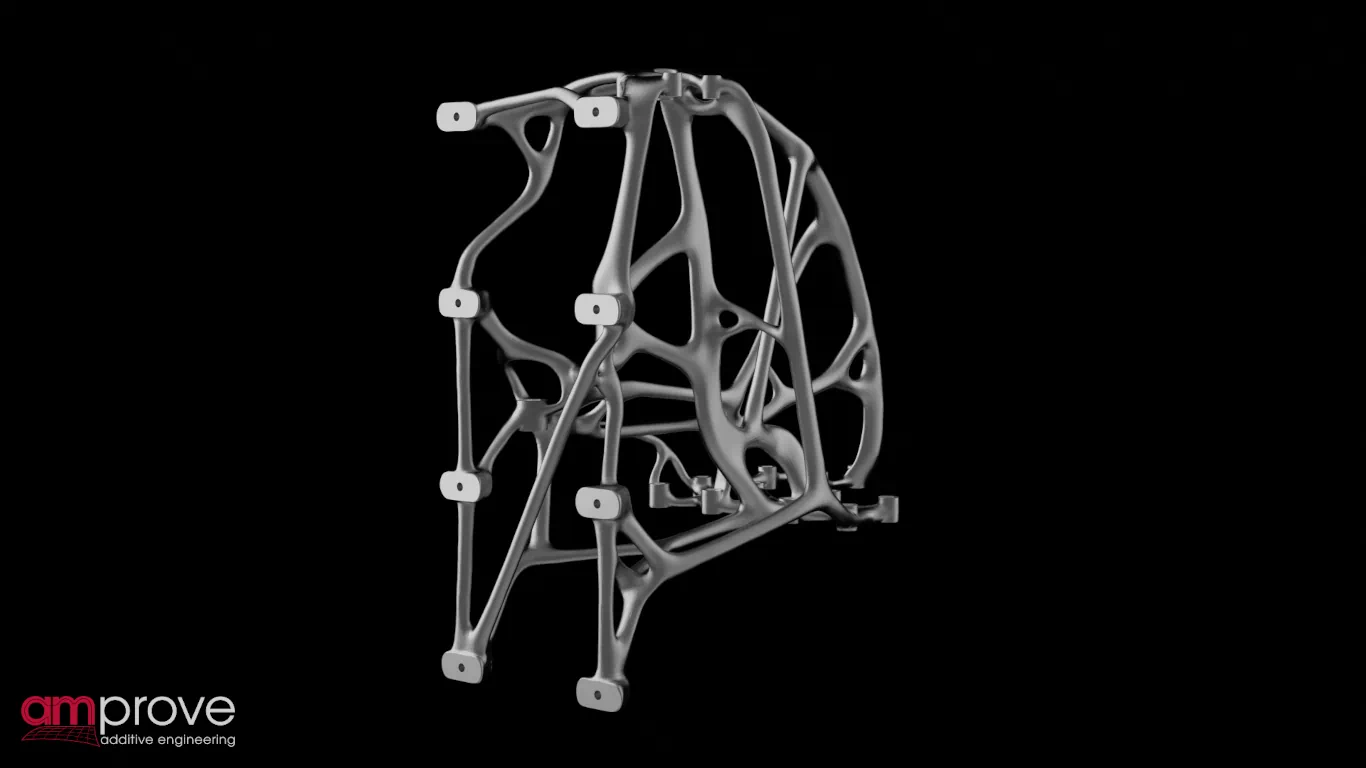

Development example - Automotive

Lightweight brake caliper for performance vehicles (fixed caliper)

Medium size series

Mass reduction

-22 % (600g)Stiffness increase

+35% (-0.67ml @ 150 bar)Max. stress

230 MPaMax. operating temperature

250°CManufacturing process

Casting with permanent moldsApplication

High powered vehiclesIn order to meet the requirements of a series with medium quantities (10,000 – 100,000 vehicles per year), the aluminum brake caliper in this version was developed for casting with permanent molds. Compared to the standard caliper, this design offers lower manufacturing costs in addition to reduced fuel consumption due to its lower mass. At the same time, the reduction in unsprung mass results in advantages for the vehicle’s driving dynamics.

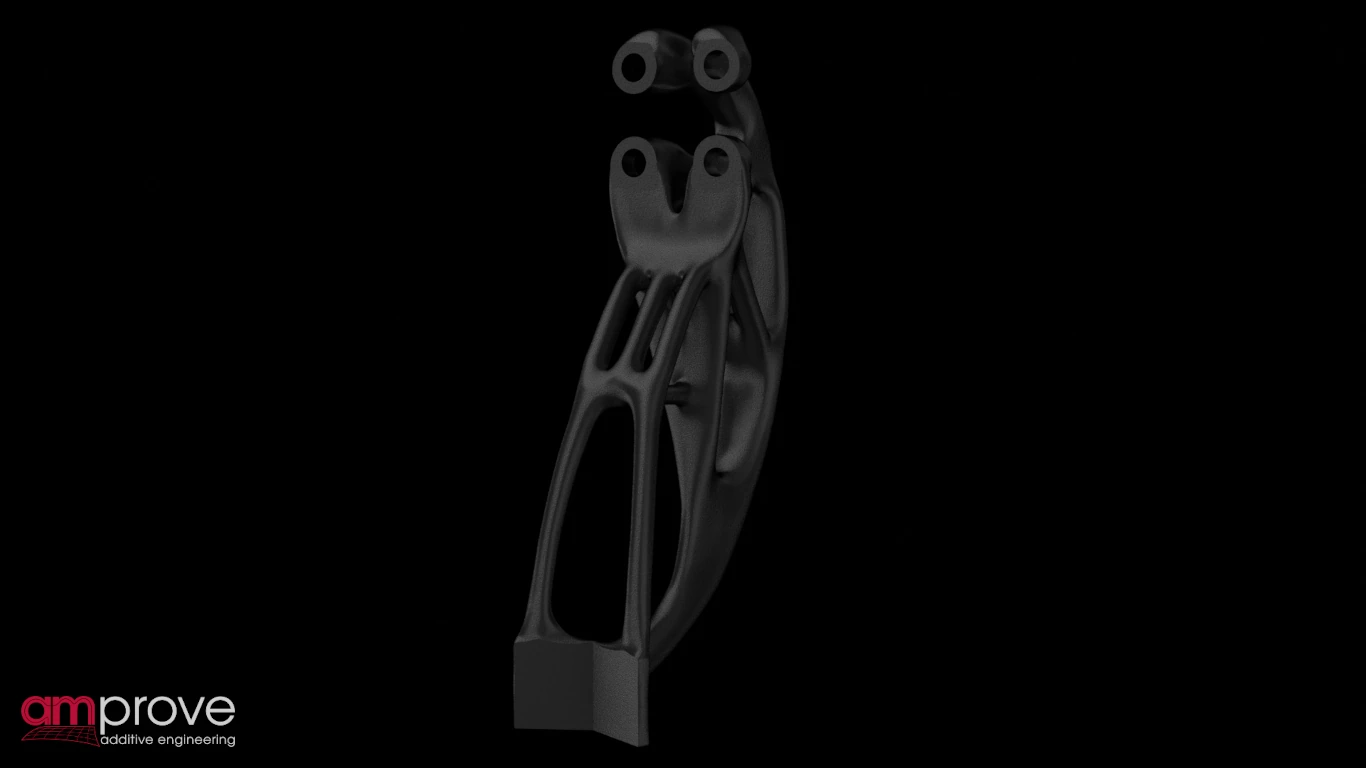

Low size series

Mass reduction

-39 % (1060g)Stiffness increase

+40 % (-0,77ml @ 150 bar)Max. stress

230 MPaMax. operating temperature

315°CManufacturing process

Selective laser meltingApplication

Supersport car, motorsportFor the application of the brake caliper in small series, the component was optimized for tool-less 3D printing. The design freedom of 3D printing enables further material savings and the creation of high-performance components. Our developments drastically reduces the mass of the component and thus the machine time required for production. This is crucial since the cost of 3D printing depends largely on this machine time, and therefore, we are keeping the price as low as possible.

We would be happy to discuss possible applications for your vehicles and to identify other potential components

How we develop components

Simulation replaces CAD-construction

Load & design space definition

Based on existing information such as CAD data, values for applied forces and pressures, information on masses and directions of motion, or photos and videos of your application, the maximum available installation space is designed and the finite element model with all load cases is built. Ideally, simulation models and design spaces already exist. In general, the more data provided, the closer the result is to the optimum.

Topology & shape Optimization

Topology and shape optimizations are performed within the developed design space. For the given load cases, the geometry is optimized under suitable restrictions with regard to the optimization objective, e.g. minimizing the mass. During this process, all constraints are defined keeping in mind the desired production process to ensure manufacturability. Both conventional manufacturing processes such as casting and milling as well as additive manufacturing processes (3D printing) can be taken into account. No further information is required on your part.

Geometry return

In order to preserve the optimized result of the topology and shape optimizations, further steps are taken directly on the output of the solver. The generated density distribution is fed into a parameterizable geometry, which can then be further used in all commercial CAD programs. The new geometry is a fully functional solid model, which can be exported as a STEP file, for example. The deviation between the result of the topology optimization and the final component’s geometry is very small due to the elimination of the manual post-design work.

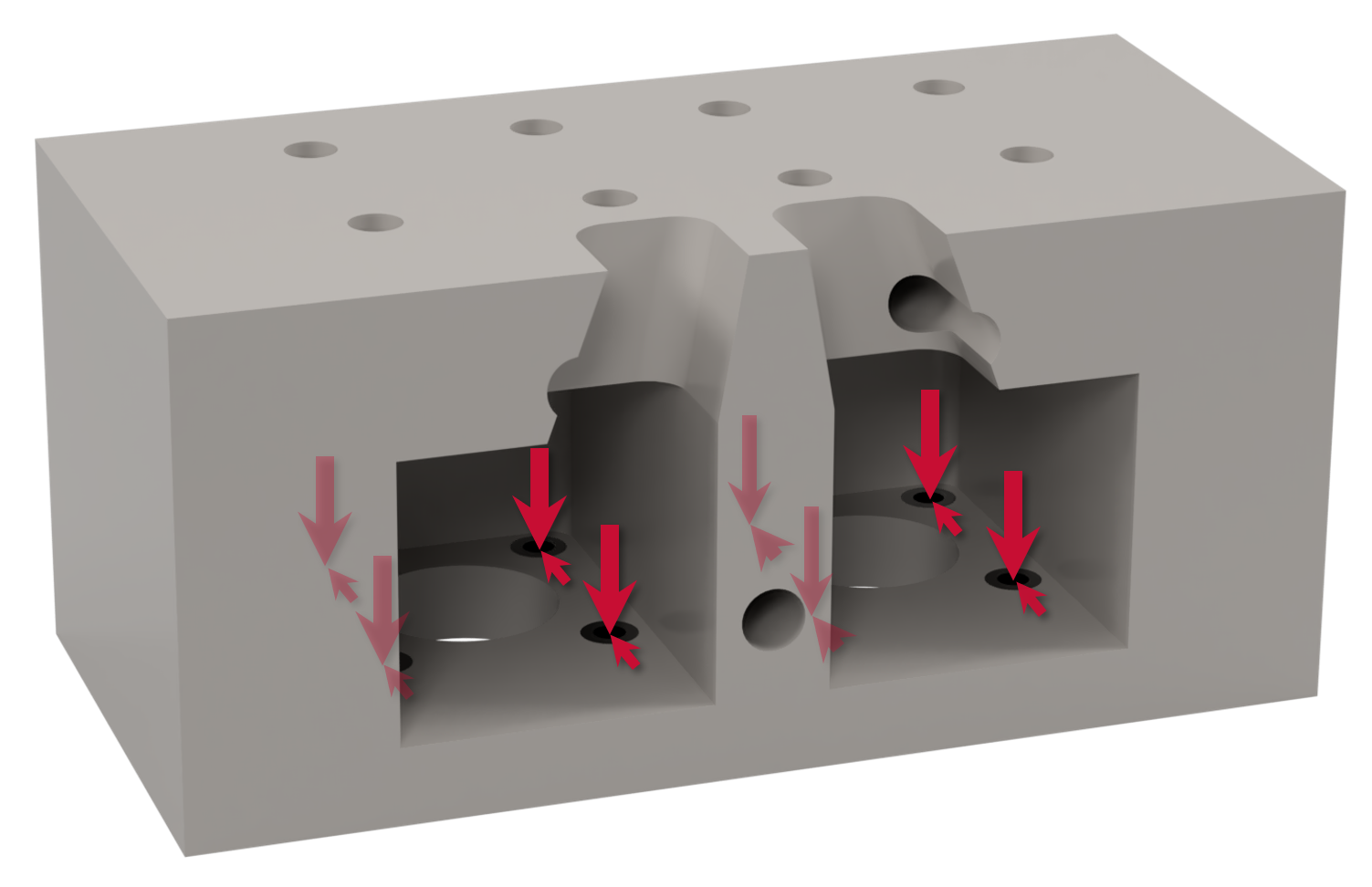

FE-Reanalysis

The result of the optimizations is then finally validated. Various simulations are considered. On one side, fatigue analyses are carried out to ensure the safe operation of the component, and on the other side, process simulations are performed to enable cost-effective and trouble-free production. Depending on the application, additional properties such as NVH behavior or thermal resistance can be taken into account. At the same time, these properties can also be prescribed as part of the optimization.

Result

The result is an optimal, fatigue-proof component that can be manufactured reliably and cost-effectively in the selected manufacturing process. Every component structure has a function. Maximum performance at minimum cost.

- Minimal weight

- Minimum production costs

- Highest stiffnes

- Ideal thermal behavior

TEAM

Dennis Middelmann

Co-Founder

Yannik Eggert

Co-Founder

Rami Bedewi

Co-Founder

Björn Ringel

Berater

Our team consists of engineers with more than fifteen years of experience in simulation-driven component development. Most of our experience comes from the automotive and motorsport sector. There we dealt with many CAE and CAD topics centered around structural optimization. In addition to conventional manufacturing processes such as casting and milling, we have increasingly focused on various additive manufacturing processes (3D printing).

About us

improve by amprove.

Our Vision

With simulation driven component development, practically any component can be driven to its maximum efficiency and performance. Contrary to popular assumptions, manufacturing costs are often reduced rather than increased during this process. Our desire is to update the hardware world with our development work and to do our part to reduce unnecessary material waste. As a company, we aspire to act as a part supplier in the future by building up a portfolio of self-developed, efficient hardware.

Contact

- +49 (0) 176 4200 2810

- kontakt(at)amprove.de

Partners